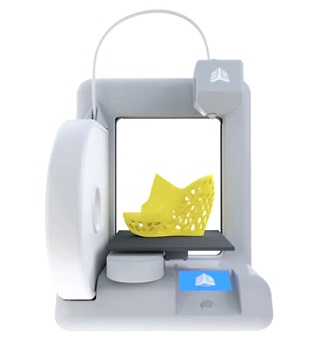

Plastic Jet Printing or PJP is another 3D printing technology that uses heat and pressure to extrude a continuous bead of material. Plastic thermoplastics are the only material used in PJP 3D printing. PJP is fairly similar to Fused Deposition Modeling and Fused Filament Fabrication, however, PJP printers are intended to be purely consumer models.

Plastic Jet Printing process:

- First, a STL file is created from a 3D CAD model. STL is an industry-standard file extension that “slices” your 3D model in a stack of cross-sections. Information about these cross-sections is then used to print the model.

- The file is then sent to the machine’s software – supports are usually created automatically at this point. In some cases, you may have to convert your file into another format proprietary to the specific 3D printer you’re using.

- The print tip and the print pad of the printer will start a heating process which typically lasts about 10 minutes. Once the preset temperatures are reached, printing of the model will begin.

- The raw material – thin plastic filament – is fed through the heated print tip. The print tip melts the filament and “draws” with it a cross-section of the model on the print pad. In some cases, the print tip only moves across one horizontal axis. This means that the print pad has to move across another horizontal axis as well.

- After a cross-section is “drawn”, the print pad is lowered by the thickness of the layer.

- Steps 4-5 are repeated until all cross-sections of the model are printed on top of each other.

- Once all the cross-sections are printed, the model is completed. The print pad is then removed from the printer and both it and the model are left to soak in warm water until the model is separated from the pad.

- If present, supports are removed. This is done manually, usually with pliers, or by hand.

PJP Materials

The only material PJP can work with is a thermoplastic. However, thermoplastics enable the creation of fairly functional, durable parts. You probably won’t be able to print a very strong part, but it will be as robust as most injection-molded plastic parts.

Actually, the infamous 3D-printed lower reciever for an assault rifle was created using ABS plastic – a typical raw material used by PJP printers.

The material is also safe and office-friendly, meaning you can print custom-designed forks and knives and be confident that they are not poisoning you. And, of course you can print prototypes using PJP – provided they aren’t too big and don’t need to have exact dimensional properties.

Disadvantages of plastic jet printing

Unfortunately, strict dimensional properties are where PJP 3D printing technology comes up a little short, but as the technology advances tolerances are improving.

PJP also doesn’t have a great surface finish – certainly not as good as SLA surface properties. However, it’s still fairly decent compared to other 3D printing technologies like SLS.

Least expensive consumer option!

When the price is taken into consideration, plastic jet printing becomes very attractive. Price is the main reason why PJP is becoming the most coming 3D printing technology for consumers. A relatively low-cost PJP printer might some day find a place in every home!

Comments are closed, but trackbacks and pingbacks are open.